“Cobots are technological marvels”, says Tony Thompson, managing director of ALM Engineering Solutions.

“They’re revolutionising the manufacturing process.”

Collaborative robots – or ‘cobots’ – are, indeed, having a huge impact on the manufacturing sector and are increasingly working peacefully side-by-side with their human colleagues.

And given that cobots tend to cost less than traditional robots, many more companies are able to afford them, specifically for slower and smaller production runs.

With robotics and machinery accounting for over 50 per cent of Industry 4.0 M&A transactions globally, it’s now clear that this technology is shaping up to be the next frontier in manufacturing.

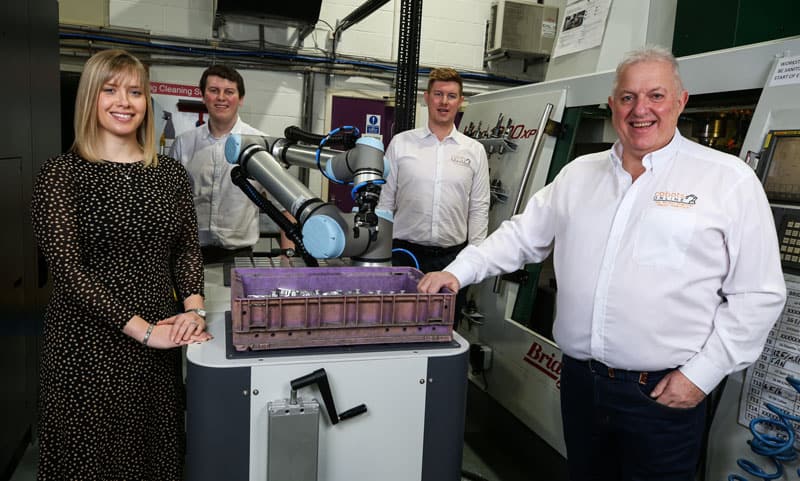

Located in Heighington Lane Business Park, Newton Aycliffe, Cobots Online is an extension of the ALM Engineering Solutions business, offering an extensive range of collaborative robots, associated end of arm tooling (EOAT), maintenance and after sales services.

Founded in 1994, ALM Engineering is essentially a family-owned business, with first class precision engineering services as its main focus of operation.

However, with the rise of the cobots, Tony believes the future of manufacturing and other prominent sectors like packaging, food processing, warehousing, pharmaceuticals, oil and gas and marine et al – is all about automation.

“Whether you’re a manufacturer or a service provider, automation is the key to future success,” says Tony.

“If you haven’t considered automation as part of your long-term growth plans, then your competitors will have. The benefits of automation, particularly with the use of cobots, are so compelling that implementing automation should be at the forefront of every manufacturer’s thinking.”

Tony has a valid point. Cobots are a breed apart from the industrial robots of years past. They are exceptionally easy to set up, often programmed through a tablet or even by simply adjusting an arm, and they can be installed in a matter of hours.

They are flexible and mobile, don’t need much space and can be redeployed to support new and multiple applications with consummate ease.

Furthermore, they are very safe and are designed to stop or adjust their speed if workplace safety is compromised.

The potential of this technology to reduce costs in manufacturing is obvious and verifiable. Companies such as Ford and Amazon have shown the way, and advances in technology are now allowing smaller businesses to follow in their footsteps.

To take advantage of the expected dynamic growth in cobot sales, Cobots Online are aiming to position themselves as the premier Cobot integrator in the North of England.

The company has already secured partnerships with some of the world’s most innovative cobot manufacturers – like Universal Robots, Doosan and OnRobot – and are poised to take advantage of market growth.

But Tony is adamant that it’s not only the technology that will drive market growth, but also how cobot integrators will adapt to fast moving technological changes and the levels of service that will accompany each cobot sale.

“We’re a family-owned and run business which makes us take our promises seriously,” he says.

“Our business depends on highly satisfied customers and we’re very aware of this. We’re also a manufacturing business ourselves and we understand our clients’ challenges because we face the same ones.”

Tony is also acutely aware that cobot engineers speak the same language as their clients.

He adds: “We’re not robotic about robotics – we talk about loading and unloading machines, screw driving, welding, loading pallets, remotely operating inspection tasks such as loading/unloading CMM’s, picking and placing parts on an assembly line.

“We talk about your process in a language you understand and we help you to identify and explore the best way to get the results which make a positive difference to your business.”

Currently, there is a breadth of possibilities for cobots in manufacturing. The exciting thing is that as the enabling technologies develop further, cobots will become ever more useful and pervasive in industry.

The future is most certainly robotic, but as to whether we are to expect a cobot takeover, the industry has been quick to put any anxious minds at rest.

For the time being, at least, robots are sticking to the three Ds – the dirty, the dull and the dangerous.

Find out more at cobotsonline.co.uk.